If you’re interested in learning how to make your own biodiesel the first steps are simple and easy; don’t jump right into building a processor, titrating waste oil, processing big batches, and risking producing poor quality biodiesel. Start out with a 1 liter “test batch” using new vegetable oil to learn the basic chemistry – there’s little risk and you’re almost certain to end up with good results! Familiarize yourself with this tutorial so when we publish our designs and instructions for the “Innovative Biodiesel Project,” you’ll be good to go! – Ryan King.

Safety first:

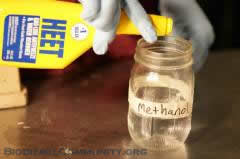

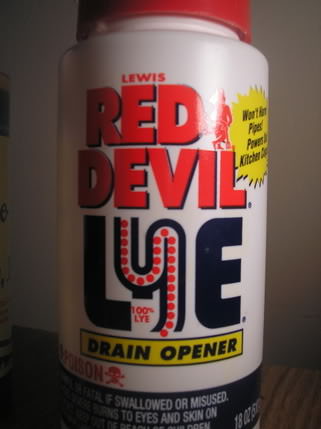

Your 2 primary reagents are lye and methanol – learn how to store, handle, and work with these chemicals in small amounts before moving on to large quantities.

KOH and NaOH (both referred to as lye) are caustic and must be handled with gloves. Breathing masks are recommended when handling large amounts of lye – if the dust is inhaled, it can burn the nasal passageway and respiratory system. Lye reacts with aluminum, tin and zinc. Use HDPE (High-Density Polyethylene) or #2 plastic, glass, enamel or stainless steel containers for lye and methoxide. Lye is also hygroscopic, meaning it absorbs moisture from the air. Care must be maintained during storage and weighing to avoid prolonged exposure to open air. Lye containers must be airtight, and weighing should be performed quickly in a dry, safe location.

Methanol is also hygroscopic and must be stored in air tight containers. Methanol has a high toxicity in humans. If as little as 10 mL of pure methanol is ingested it can break down into formic acid, which can cause permanent blindness. As little as 30 ml of ingested methanol is potentially fatal. The initial symptoms of methanol intoxication include: central nervous system depression, headache, dizziness, nausea, lack of coordination, and confusion. Sufficiently large doses can cause unconsciousness and death. The initial symptoms of methanol exposure are usually less severe than the symptoms resulting from the ingestion of a similar quantity of ethanol. Once the initial symptoms have passed, a second set of symptoms arises, 10 to as many as 30 hours after the initial exposure to methanol, including blurring or complete loss of vision. Methanol ingestion, absorption through the skin or inhalation of fumes can be treated with ethanol, which acts as a competitive inhibitor of the hepatic enzyme alcohol dehydrogenase, preventing methanol’s conversion to toxic by-products.

Getting started:

Buy about a liter of new vegetable oil (canola, soy, sunflower or corn oil) at the grocery store. New, unused oil will not need to be dewatered or filtered. Pick up a few hundred milliliters of 99% or higher purity methanol (most automotive stores sell HEET brand antifreeze – the yellow container is pure enough for biodiesel production), and pick up some lye from a grocery or hardware store (make sure to get pure lye without coloring or added drain cleaners).

Making Biodiesel!

Start warming up your new vegetable oil on an electric stove or with passive solar (no open flames!) to a temperature of around 120-132 degrees Fahrenheit. If the oil is too hot, the methanol will start evaporating and the reaction won’t perform as well. The average amount of lye needed to fully convert 1 liter of new oil is about 3.5 grams of NaOH or about 4.9 grams of KOH. In a separate container, mix either 3.5 grams of NaOH or 4.9 grams of KOH into 200 ml of methanol until fully dissolved – use a safe container made of HDPE plastic. This is the methoxide mix – the combination of the reagent and catalyst that will break the triglycerides of the vegetable oil into individual fatty acid methyl esters (also known as “biodiesel) and a layer of settled out byproduct consisting mostly of glycerin (which you can use to make soap!). When the oil is up to temperature, carefully pour in the methoxide, close the container and shake vigorously for about 3-5 minutes. You will notice a color change, indicating the reaction is occurring. After shaking, allow the byproduct to settle out – it usually takes about 10 to 20 minutes to start noticing the separation, then a few hours for substantial byproduct to precipitate.

Here’s a short video that Make Magazine put together for a DIY biodiesel project:

Check out http://journeytoforever.org/biodiesel_make.html for more details on biodiesel test batches, and let us know if you have questions!